Whats the difference between wheeling a local 4×4 trail and an epic off-road adventure? You check your rig the day before you wheel a local trail and fix it when you get back home, on an epic off-road adventure you check your rig every morning and fix it every night.

OK, so Conan has nothing to worry about from my stand-up, but there is a lot of truth in that joke. Pilots know that you live and die by your check lists: prior to take-off, during flight and prior to landing. The same is true in wheeling, especially if you will be dependent on your rig for a number of days, with no support in sight.

Sometimes with all the excitement and work of an off-road adventure it is easy to forget something (trust me, I’ve forgotten more than my share). In order to reduce the chance of missing a potential problem, we now keep a laminated memory jogger checklist to help us stick to our inspection program before, during and after a day on the trail.

Pre-Trip / Daily – Rig Inspection

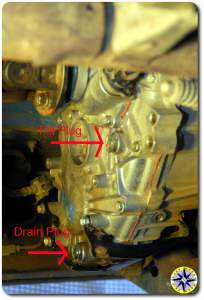

- Axles & Differentials – bolts, boots, clips, u-joints, grease points. Check to ensure everything is tight and look for leaks or drips.

- Battery – clean terminals, check for damaged, corroded wiring. Check for loose connections.

- Brakes – drums, rotors, pads/shoes, fluid, hoses, leaks, check parking brake, brake lights. Helps to have a second person pressing on the breaks while checking.

- Belts & Hoses – look for cracks or bulges. Ensure spares are packed in the parts bin.

- Body/Frame – look for cracks and rust. Remove any sticks and debris caught up in the frame.

- Cooling/Heating system – look for leaks, fluid levels, clean and repair fins, check hoses and clamps, thermostat, radiator cap. Ensure leak repair kit is packed in parts bin.

- Communications – CB / ham radio, antenna broadcast and receive.

- Driveline/Transmission – inspect case and shifter, leaks, fluids, universal & CV joints, skid plates

- Engine – carburetor, fuel injectors, spark plugs, wires, PVC valve, pumps, distributor & wire, check for leaks and cracks, air filter (clean or replace). Keep an eye out for loose wires and hoses.

- Exhaust – muffler, tailpipes (rust or holes or hanging). Check all hardware holding tailpipes in place.

- Fluids – oil, transmission, brake, radiator coolant, gear oils, wipers, power steering (check levels and color). Ensure extra fluids packed in rig.

- Lights – headlights, brake lights, auxiliary lights; make sure they’re aimed properly. Verify turn signals. Ensure extra bulbs packed in parts bin.

- Steering – check alignment, fluid level, belts and hoses, pump and reservoir. Look for leaks. Check tie-rod boots for tears or rips. Check all joints for play.

- Suspension – coil overs, springs, shocks, alignment, wheel bearings, steering linkage, control arms, pan bars. Notice unusual play in components.

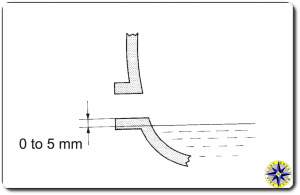

- Tires – tighten (torque) lug nuts, air pressure, tread wear (including your full-size spare), look for cuts and missing chunks, torque beadlock bolts. Ensure auxiliary air pump or CO2 tank is operational and packed in the rig.

- Winch – free spool rope and inspect, rewind onto drum. Check for loose connections and look for frayed rope or wires.

- Wipers – check for wear, fluid level.

Trail Head – Rig Inspection

Before you take off for the trail start the engine and inspect the following with while the rig warms up:

- Fuel level – check fuel gauge ensuring level is on full (plan for next fuel stop if necessary).

- Voltage – check voltage gauge for proper level.

- Oil pressure – check oil pressure gauge for proper pressure.

- Engine RPMs – check tachometer to ensure smooth maintained engine idle speed. Listen for misfires and unusual engine noise. (you should know your rig’s personality including how its engine sounds normally)

- Temperature – check temperature gauge to see proper operation and coolant temperature.

- Transfer case – ensure transfer case engages in 4 wheel high and 4 wheel low as well as disengages smoothly.

- Traction control – test that the rear locker engages correctly. Test A-trac (or front locker) for proper engagement. Make sure the disengage as well.

- Load – ensure load is properly secured. Check hi-lift jack, shovel and any exterior mounted items.

- Walk around – make one last walk around the rig. Look for any item left out. Ensure valve stem caps are screwed on after airing down. Check that nothing was left resting on the spare, bumper, hood or roof.

If you are on a multi-day off-road adventure stop early enough so that you can fully inspect your rig for damage while the sun is still out. Stopping early also gives you enough daylight to see what you are doing if repairs are needed. Tip: remember fluid levels change based on the engine temperature always read against the appropriate level marks.

While a checklist wont prevent breakage, it will go a long way to lessening potential problems. By catching leaks, tears and loose bolts early on, you can hopefully avoid finding yourself trying to reconnect a break line while standing in axle deep mud. But just in case all hell breaks loose… carry lots of duct tape.